Call us now :+8613817284737

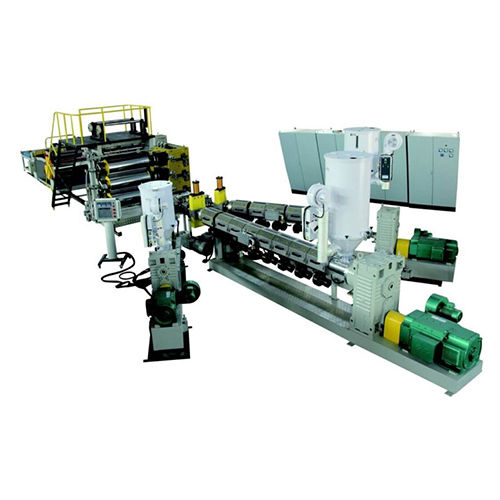

Multi-Layers Co-Extrusion PPM-PP Luggage Plate Extrusion Line

Price 150000 USD ($)/ Unit

MOQ : 1 Unit

Multi-Layers Co-Extrusion PPM-PP Luggage Plate Extrusion Line Specification

- Product Type

- Multi-layers Co-extrusion PPM-PP Luggage Plate Extrusion Line

- Power Source

- Electricity

- Operating Type

- Automatic

- Surface Treatment

- Coated

- Color

- Gray

- Warranty

- 1 Year

- Usage & Applications

- Industrial

Multi-Layers Co-Extrusion PPM-PP Luggage Plate Extrusion Line Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Multi-Layers Co-Extrusion PPM-PP Luggage Plate Extrusion Line

This manufacturing lines design is unique (it has been granted a national invention patent), and it combines advanced and mature processing technology and formula technology (it has also been granted a national invention patent). Multi-Layers Co-Extrusion PPM-PP Luggage Plate Extrusion Line can ensure that the composite modified PP sheet meets the standards and quality of plastic-absorbing forming and trolley suitcase performance requirements with light weight and low cost.

Technical Specification

|

Extruder 1: |

120x35 132KW |

|

Extruder 2: |

90 x 35 75KW |

|

Extruder 3: |

65 x 35 37/45KW |

|

Plate specification: |

Thickness: 0.8-5mm Width: 900mm or |

|

Output |

400kg/h |

Advanced Co-Extrusion Process

Employing state-of-the-art co-extrusion techniques, this line enables the production of multi-layer PPM-PP luggage plates. The process integrates different polymer materials into polished, durable sheets, offering improved strength and visual appeal for various industrial applications.

Wide Range of Industrial Applications

This extrusion line is ideal for producing luggage plates used in travel goods, packaging, and transport industries. Its versatility allows manufacturers to create customized sheets that meet the demanding requirements of industrial clients, ensuring both functionality and sleek design.

FAQs of Multi-Layers Co-Extrusion PPM-PP Luggage Plate Extrusion Line:

Q: How does the Multi-Layers Co-Extrusion PPM-PP Luggage Plate Extrusion Line operate automatically?

A: The extrusion line is equipped with advanced automation controls, allowing users to set and manage production parameters with minimal manual intervention. This ensures consistent output and reduces labor requirements, making it highly efficient for industrial-scale manufacturing.Q: What is the process for producing luggage plates using this extrusion line?

A: The process involves feeding PPM and PP materials into separate extruders, which merge during co-extrusion to form multi-layer plates. The materials are coated and passed through calibration and cooling units to achieve the final gray-colored, durable surface preferred in industrial applications.Q: When can users expect after-sales support and warranty services?

A: The manufacturer offers a one-year warranty from the date of delivery, covering technical support and repair services. Customers can access assistance during regular business hours or as specified by the supplier, ensuring optimal machine performance throughout the warranty period.Q: Where is this luggage plate extrusion line manufactured and exported from?

A: This extrusion line is manufactured in China and distributed globally through various authorized channels including exporters, suppliers, and traders. Clients benefit from the wide reach and reliability of the established distributor network.Q: What are the benefits of using this extrusion line for luggage plate manufacturing?

A: Users gain advantages such as improved Plate durability, uniform surface finishing, rapid automatic operation, and the flexibility to produce customized products for diverse industrial requirements. The coated multi-layer output ensures resilience against environmental factors.Q: How can this extrusion line be utilized for industrial applications?

A: The line is designed for continuous, high-volume production and is suitable for factories producing luggage, packaging sheets, and other industrial goods that require sturdy, multi-layer plates. Its automated operation allows integration into existing manufacturing processes seamlessly.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Luggage Line Category

ABS And PC-ABS Alloy Multi-Layers Co-Extrusion Luggage Plate Extrusion Line

Price 170000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Operating Type : Automatic

Color : White & Gray

Usage & Applications : Industrial

PC Multi-Layers Co-Extrusion Luggage Sheet Extrusion Line

Price 130000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Operating Type : Automatic

Color : White & Yellow

Usage & Applications : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry