Call us now :+8613817284737

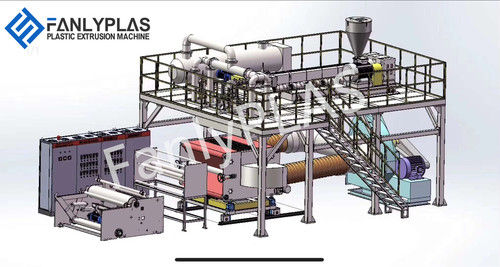

PP Melt Blown Non Woven Fabric Machine

MOQ : 1 Unit

PP Melt Blown Non Woven Fabric Machine Specification

- Operating Temperature

- Up to 300C

- Machine Type

- Automatic Melt Blown Fabric Machine

- Plastic Processed

- Polypropylene (PP)

- Model No

- MBF-1600

- Production Capacity

- 350-400 kg/hr

- Connectivity Options

- Touch Screen HMI, Remote Diagnosis

- Voltage

- 380 V

- Frame Type

- Heavy Duty Frame

- Control System

- PLC Control System

- Drive

- AC Servo Drive

- Cooling System

- Water Cooling

- Frequency

- 50 Hz

- Features

- High Output, Energy Efficient, Low Maintenance

- Noise Level

- <85 dB

- Motor Power

- 22 kW

- Power Rating

- 180 kW

- Accuracy

- 0.5 mm

- Lubricating System

- Automatic Lubrication

- Product Type

- Other

- Technology

- Melt Blown Technology

- Power Source

- Electricity

- Operating Type

- Automatic

- Power

- 120-180 kW

- Pressure

- 0.8 Mpa

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 8500 x 2700 x 4500 mm

- Weight (kg)

- 9500 kg

- Color

- Blue / White

- Usage & Applications

- Industrial

- Die Width

- 1600 mm

- Number of Operators

- 1-2 persons

- Heating Method

- Electric Heating by Ceramic Heaters

- Raw Material

- Polypropylene Granules

- Air Pressure Required

- 0.6-0.8 Mpa

- Filtration Fineness

- 1-5 Micron

- Working Speed

- Adjustable, up to 100 m/min

- Spinning Speed

- High Speed

- Operator Interface

- Color Touch Panel

- Roller Type

- Anti-static Roller

- Installation Support

- Available

- Safety Features

- Emergency Stop, Overload Protection

PP Melt Blown Non Woven Fabric Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About PP Melt Blown Non Woven Fabric Machine

We pay attention on:

1. Better screw design to make the PP melt flow rate more stable

2. Materbatch feeder to increase the static absorption and increase the fabric filtering rate and barriers.

3. Double column screen change to filt the dust make sure it will not block thepinneret board

4. Stable and strong web forming machine with electrical control makes product more stable moving

5. Static treatment Unit

6. Round knife slitting

7. Automatic winder

Precision Filtration and High Output

Engineered for exacting industrial requirements, this melt blown fabric machine delivers filtration fineness from 1 to 5 microns, ensuring superior product quality. Its robust design yields production rates between 350 and 400 kilograms per hour, making it ideal for large-scale manufacturing environments demanding consistent, high-quality output.

Advanced Automation and User-Friendly Controls

With a sophisticated PLC control system and a color touch panel interface, this machine streamlines operation and monitoring, requiring only 12 operators. Features such as automatic lubrication, emergency stop, and overload protection enhance safety and minimize manual intervention, allowing for heightened operational efficiency.

Durable and Energy Efficient Design

Built on a heavy-duty powder-coated frame, the MBF-1600 integrates energy-saving components, such as AC servo drives and efficient ceramic heaters. Its adjustable working speed and water cooling promote longevity and adaptability, while remote diagnosis and touch screen HMI foster quick support and process adjustments.

FAQs of PP Melt Blown Non Woven Fabric Machine:

Q: How does the PP Melt Blown Non Woven Fabric Machine operate and what is the production process?

A: The machine utilizes melt blown technology, processing polypropylene granules through ceramic heaters to create fine microfibers, which are then collected onto the anti-static roller to form non woven fabric. The automated PLC system ensures precise control throughout the process, with adjustable spinning and working speeds to meet various industrial requirements.Q: What are the main benefits of using this melt blown fabric machine in industrial applications?

A: Key advantages include high output (up to 400 kg/hr), energy efficiency, low maintenance due to automatic lubrication, and exceptional filtration fineness. Its advanced safety functions and user-friendly interface minimize downtime, while robust construction ensures durability and consistent performance in demanding environments.Q: When is installation support provided for the MBF-1600 non woven fabric machine?

A: Comprehensive installation support is available at the time of delivery. The manufacturer offers assistance with setup, calibration, and operator training to ensure efficient and correct commissioning, maximizing initial operational effectiveness.Q: Where is the best environment to install and operate this machine?

A: The MBF-1600 is ideal for spacious industrial areas with stable electrical supply (380 V, 50 Hz) and adequate water access for the cooling system. Proper ventilation, safety protocols, and access to compressed air (0.60.8 Mpa) will help optimize its performance and maintain optimal working conditions.Q: What kind of maintenance is required and how frequently should it be performed?

A: Routine maintenance is minimal due to automatic lubrication, but regular inspections of the heating elements, rollers, and filtration system are recommended. Cleaning and checking the water-cooling and safety systems will prevent unexpected downtime and prolong machine life.Q: How many operators are required and what experience is necessary to manage the machine?

A: The machine is designed for efficiency, typically requiring just one or two operators. Basic technical knowledge and training in operating the touch screen HMI and PLC system are sufficient, as the manufacturer provides comprehensive training during installation.Q: What are the available connectivity and control options for remote monitoring or troubleshooting?

A: The machine includes a touch screen HMI interface with options for remote diagnosis, allowing technicians to monitor operating parameters, identify faults, and consult with support specialists for real-time troubleshooting and system optimization.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Melt-Blown Fabric Making Machine Category

1.6 m Wide PP Melt Blown Fabric Making Machine

Price Range 20000.00 - 150000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power : 220240 Volt (v)

Features : High Efficiency, Nonwoven Output, Energy Saving, User Friendly Interface

Usage & Applications : Industrial

Motor Power : 15 kW

600mm width PP Melt Blown Non Woven Fabric Machine

Price Range 20000.00 - 150000.00 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power : 55 kW

Features : High Efficiency, Stable Performance, Low Maintenance

Usage & Applications : Industrial

Motor Power : 7.5 kW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry