Call us now :+8613817284737

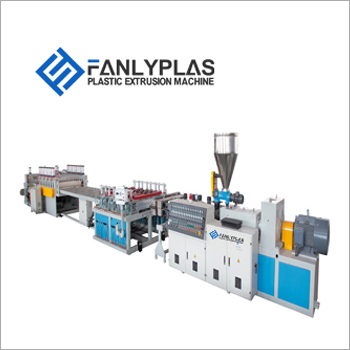

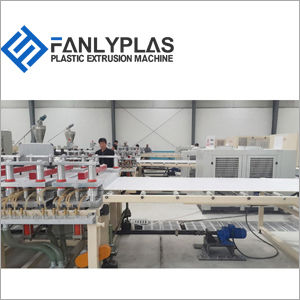

WPC Foam Door Panel Line

Price 30000 USD ($)/ Set

MOQ : 1 Set

WPC Foam Door Panel Line Specification

- Machine Type

- Twin Screw Extruder Line

- Drive

- AC Motor

- Accuracy

- 0.2 mm

- Frame Type

- Heavy Duty Steel Frame

- Cooling System

- Water or Air Cooled

- Power Rating

- 150 kW

- Motor Power

- 22-30 Kilowatt (kW)

- Noise Level

- 75 db

- Features

- High-Speed Production, Energy Efficient, Low Maintenance, Corrosion Resistant

- Lubricating System

- Automatic

- Control System

- PLC Automatic Control

- Operating Temperature

- 0-45 Celsius (oC)

- Model No

- WPCDL-1300

- Frequency

- 50/60 Hertz (HZ)

- Connectivity Options

- Ethernet, USB

- Voltage

- 380 / 415 Volt (v)

- Production Capacity

- 300-500 Kg/hr

- Plastic Processed

- PVC/WPC

- Product Type

- Coating Line

- Technology

- Extrusion & Co-Extrusion

- Power Source

- Electricity

- Operating Type

- Automatic

- Pressure

- 0.6-0.8 mpa

- Surface Treatment

- PVC/WPC Foil Laminated, Polished or Embossed

- Dimension (L*W*H)

- 30000*2500*2500 Millimeter (mm)

- Weight (kg)

- 18000 Kilograms (kg)

- Color

- Customizable

- Usage & Applications

- Industrial

- Haul-Off Unit

- 6/8 Rubber Block Haul-off

- Installation Service

- On-Site Available

- Heating System

- Ceramic Band Heater

- Feeding System

- Vacuum Hopper Loader

- Raw Material

- PVC Resin, Wood Powder, Additives

- After Sales Support

- 24/7 Online & On-Site Support

- Cutting System

- Automatic Tracking Cutter

- Calibration Table Length

- 6000 mm

- Panel Width

- 600-1200 mm

- Screw Design

- Parallel, High Output Efficiency

- Working Speed

- 0.5-6 m/min

- Line Configuration

- Single or Multiple Output Lines Available

- Panel Thickness

- 20-45 mm

- Stacking System

- Auto Stacker

WPC Foam Door Panel Line Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 15 Days

- Main Export Market(s)

- South America, Central America, Western Europe, Australia, North America, Eastern Europe, Middle East, Asia, Africa

About WPC Foam Door Panel Line

Product description:| WPC Foam Door Panel LineMain technical specification | |||

| Extruder model | |||

| Production width | 1220mm | 1560mm | 2050mm |

| Production thickness | 1-5mm | 1-5mm | 1-5mm |

| Extruder model | SJZ80/156 | SJZ80/156 | SJZ80/156 |

| Capacity(Max) | 400kgh | 400kgh | 400kgh |

| Main motor power | 75kw | 75kw | 75kw |

Features of WPC Door Panel

1.No painting or varnishing, Waterproof, fire retarding, wearing resistance, corrosion resistance, mildew proof and good insulation.

2.Healthy and environmentally friendly (lead free)

3.Light weight, easy for installation and maintenance.

4.It can be further processed, like drilling, sawing, nailing, and bonding with other PVC material, etc.

Raw Materials

Natural fibers:wood waste, saw mill waste, wood powder, wood flour, wood chips, bagasse, bamboo, coir fibers, rice husk, cotton stalks

Polymers: PVC virgin and PVC recycled

Shanghai Fanly Plas asa well-knownplastic extrusion machinerysuppliers and plasticturn key project provider. Weprovidehigh qualityextruderandextrusion linesfor different countries customers.

High Output Efficiency & Automated Production

Experience streamlined manufacturing with the WPC Foam Door Panel Line, offering high-speed, energy-efficient production. Its automatic calibration, cutting, and stacking systems minimize manual intervention and downtime, ensuring consistent quality and throughput at 0.56 m/min. The precision-driven PLC controls with 0.2 mm accuracy allow for reliable panel fabrication, optimized for industrial requirements.

Customizable Panel Specifications & Surface Finishes

The line supports adjustable panel thickness (2045 mm) and width (6001200 mm), accommodating diverse application needs. Surface treatments include PVC/WPC foil lamination, polished, or embossed finishes, enhancing both aesthetics and durability. With a customizable color palette and flexible raw material feeding, production can be tailored to specific market demands.

Advanced Technology & Reliable Operation

Featuring parallel twin screw extrusion and co-extrusion technology, this system delivers exceptional output (up to 500 kg/hr) using robust AC motor drives. The intelligent control system, water or air cooling options, automatic lubrication, and noise mitigation (75 dB) ensure safe, stable, and low-maintenance operations, supported by 24/7 online and on-site after-sales assistance.

FAQs of WPC Foam Door Panel Line:

Q: How does the WPC Foam Door Panel Line ensure efficient and consistent production?

A: The line integrates high-output twin screw extrusion with automatic feeding, calibration, haul-off, cutting, and stacking systems. PLC controls optimize production parameters, delivering consistent panels at speeds of 0.5-6 m/min with minimal operator intervention.Q: What types of raw materials are compatible with this machine?

A: The system processes a blend of PVC resin, wood powder, and various additives. This combination ensures strength and durability in the final WPC foam door panels.Q: When and where can installation and after-sales support services be accessed?

A: On-site installation services are available upon delivery, and users benefit from 24/7 online and on-site after-sales support provided by the manufacturer, exporter, or distributor.Q: What is the process of panel production in the WPC Foam Door Panel Line?

A: Raw materials are loaded via vacuum hopper, then conveyed to the extruder where extrusion and co-extrusion shape the panels. Calibration ensures desired thickness and width, followed by automated haul-off, cutting, surface finishing, and stacking.Q: Where can this machine be used and for what applications?

A: Engineered for industrial environments, the line is ideal for manufacturers producing PVC/WPC door panels used in construction, interior design, and real estate development.Q: What benefits does this panel line offer compared to traditional production methods?

A: Users gain increased productivity, lower energy costs, reduced maintenance, improved accuracy (0.2 mm), and enhanced panel quality through automated processing and advanced materials technology.Q: How can the surface appearance of the panels be customized?

A: Surface finishes such as foil laminated, polished, or embossed options, along with customizable colors, are offered. These can be selected and configured according to buyer preferences and market requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sheet And Board Production Line Category

PVC Decoration Sheet Line

Price Range 25000.00 - 150000.00 INR / Set

Minimum Order Quantity : 1 Set

Production Capacity : 400600 kg/hr

Product Type : Other, Production Line

Voltage : 380V/440V (Customizable)

Operating Type : Automatic

ACP Aluminum Composite Panel Machine

Price Range 25000.00 - 150000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Production Capacity : Up to 4000 m/Day

Product Type : Other

Voltage : 380V

Operating Type : Automatic

PC PP PE Hollow Grid Sheets Extrusion Lines

Price Range 25000.00 - 150000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Production Capacity : 9001200 kg/hr

Product Type : Other, Production Line

Voltage : 380V

Operating Type : Automatic

PVC Foam Door Panel Line

Price Range 25000.00 - 150000.00 USD ($) / Set

Minimum Order Quantity : 1 , , Set

Production Capacity : 400700 kg/h

Product Type : Other, Production Line

Voltage : 380V, 50Hz, 3 Phase

Operating Type : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry