Call us now :+8613817284737

PVC Foam Sheet Line

MOQ : 1 Set

PVC Foam Sheet Line Specification

- Control System

- PLC control system

- Cooling System

- Water cooling & air cooling

- Operating Temperature

- Up to 240C

- Production Capacity

- 400-700 kg/h

- Machine Type

- Plastic Sheet Extrusion Machine

- Power Rating

- Three Phase

- Frame Type

- Heavy duty

- Noise Level

- 85 dB

- Drive

- AC motor

- Plastic Processed

- PVC

- Lubricating System

- Automatic

- Features

- Energy efficient, stable operation, easy maintenance

- Connectivity Options

- Touch screen interface, Ethernet (optional)

- Motor Power

- 75-110 kW

- Voltage

- 380V/415V

- Frequency

- 50/60 Hz

- Model No

- SJSZ80/156

- Accuracy

- High precision

- Product Type

- Other

- Technology

- Twin screw extrusion technology

- Power Source

- Electricity

- Operating Type

- Automatic

- Power

- 110-180 kW

- Pressure

- 0.6-0.8 MPa

- Surface Treatment

- Smooth or Embossed

- Dimension (L*W*H)

- 28000 x 2000 x 2600 mm

- Weight (kg)

- 15000 kg

- Color

- White, Grey or Customized

- Usage & Applications

- Industrial

- Screw Diameter

- 80 mm / 92 mm

- Extrusion Output

- Up to 700 kg/h

- Die Structure

- Coat hanger type

- Working Speed

- 0.5-8 m/min

- Applicable Standard

- ISO, CE certified equipment

- Sheet Thickness Range

- 3-20 mm

- Operation Panel

- Digital display with real-time monitoring

- Max Sheet Width

- 1220 mm

- Roller Type

- Three roller calendar

- Dehumidifying System

- Integrated

- Safety Features

- Emergency stop, Overload protection, Interlock system

- Conveying System

- Roller-driven conveyer belt

- Feeding System

- Volumetric hopper feeder

- Cutting Unit

- Automatic precision cutter

- Heating Zones

- 5-6 zones

- Extruder Specification

- Twin Screw Extruder, SJSZ Series

PVC Foam Sheet Line Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

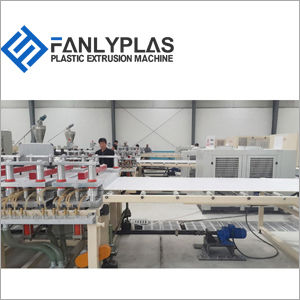

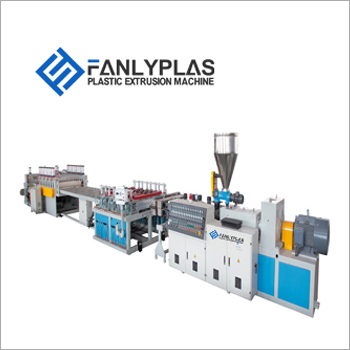

About PVC Foam Sheet Line

Introducing the eminent Fanlyplas PVC Foam Sheet Line, now available for a limited time at a monumental markdown! Engineered with unrivaled precision, this SJSZ Series Twin Screw Extruder delivers high output (up to 700 kg/h) and exceptional sheet quality across a 3-20 mm thickness range. The line is fully automatic, operating with advanced PLC controls and integrated safety systems for seamless, stable operation. Boasting ISO and CE certifications, its robust frame, energy-efficient design, and automatic lubricating system make it indispensable for industrial applications. Get it now and elevate your production capabilities!

PVC Foam Sheet Line Applications & Suitability

The Fanlyplas PVC Foam Sheet Line is widely used as an essential solution for interior wall panels, advertising signage, furniture, construction boards, and more. This line is suitable for use in manufacturing environments requiring rapid, consistent output and dimensional accuracy. It is used for producing strong, lightweight, and durable foam sheets across diverse industries, offering flexibility for customized color, surface treatments, and thicknesses based on specific operational demands.

Packaging, Samples, and Domestic Market Focus

Our premium PVC Foam Sheet Line is carefully packaged to ensure secure delivery, reflecting our commitment to quality at every outlay. Samples can be provided for evaluation, giving customers a firsthand view of its monumental performance. The main domestic mar for this line remains vast, covering industrial manufacturers and trading companies seeking high-end, efficient extrusion capabilities for varied project requirements.

PVC Foam Sheet Line Applications & Suitability

The Fanlyplas PVC Foam Sheet Line is widely used as an essential solution for interior wall panels, advertising signage, furniture, construction boards, and more. This line is suitable for use in manufacturing environments requiring rapid, consistent output and dimensional accuracy. It is used for producing strong, lightweight, and durable foam sheets across diverse industries, offering flexibility for customized color, surface treatments, and thicknesses based on specific operational demands.

Packaging, Samples, and Domestic Market Focus

Our premium PVC Foam Sheet Line is carefully packaged to ensure secure delivery, reflecting our commitment to quality at every outlay. Samples can be provided for evaluation, giving customers a firsthand view of its monumental performance. The main domestic mar for this line remains vast, covering industrial manufacturers and trading companies seeking high-end, efficient extrusion capabilities for varied project requirements.

Product details

|

Brand |

Fanlyplas |

|

Material |

PVC |

|

Product thickness |

0.4-1.2mm |

|

Product width |

200-600mm |

|

Output |

150-450kg/h |

|

Layer configuration |

Mono layer |

|

Screw Design |

Conical Twin screw |

|

Line speed |

1-30m/min |

|

Model |

FLZ65/132, FLZ80/156, FLZ80/156 |

|

Motor power |

37kw,55kw,75KW |

FAQs of PVC Foam Sheet Line:

Q: How does the Fanlyplas PVC Foam Sheet Line ensure product consistency and quality?

A: The Fanlyplas line utilizes a high-precision twin screw extruder, automatic digital controls, and real-time monitoring to provide consistent, uniform sheet thickness and unrivaled quality throughout production.Q: What industries benefit most from using this PVC foam sheet extrusion machine?

A: This equipment is ideal for construction, interior decor, advertising, and furniture manufacturing, offering high efficiency for demanding industrial applications.Q: Where can the PVC Foam Sheet Line be installed and operated?

A: Designed for industrial environments, the line can be installed in manufacturing plants, distribution centers, and large-scale production facilities requiring heavy-duty, reliable machinery.Q: What process is involved in operating this extrusion line?

A: Operation involves feeding PVC material through a volumetric hopper, precise extrusion and calendaring, automatic cutting, and stable conveyingall managed via a PLC control and touch-screen interface for seamless workflow.Q: When is the best time to inquire about the limited time markdown offer?

A: We recommend reaching out promptly, as the special markdown is available for a limited time only. Contact us now to secure this eminent production solution.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sheet And Board Production Line Category

PVC Foam Door Panel Line

Price Range 25000.00 - 150000.00 USD ($) / Set

Minimum Order Quantity : 1 , , Set

Dimension (L*W*H) : 35000*2500*3000 mm

Model No : PVCDFP350

Frequency : 50 Hz

ACP Aluminum Composite Panel Machine

Price Range 25000.00 - 150000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Dimension (L*W*H) : 14000 x 2500 x 3200 mm

Model No : ACP4000X

Frequency : 5060 Hz

PVC Glazed Tiles Extrusion Lines

Price Range 25000.00 - 150000.00 USD ($)

Minimum Order Quantity : 1 Set

Dimension (L*W*H) : 26000 x 3200 x 2500 mm

Model No : PVCGTE400

Frequency : 50 Hz / 60 Hz

WPC Foam Door Panel Line

Price 30000 USD ($) / Set

Minimum Order Quantity : 1 Set

Dimension (L*W*H) : 30000*2500*2500 Millimeter (mm)

Model No : WPCDL1300

Frequency : 50/60 Hertz (HZ)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry