Call us now :+8613817284737

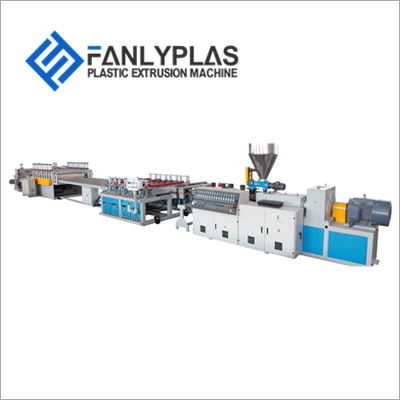

PVC Rigid Sheet Line For Sandwich Board

Price 28000.0 USD ($)/ Set

MOQ : 1 Set

PVC Rigid Sheet Line For Sandwich Board Specification

- Connectivity Options

- Ethernet / Remote Monitoring (Optional)

- Drive

- AC Motor with Frequency Inverter

- Operating Temperature

- 0-50C

- Motor Power

- 55-90 kW (Main Extruder)

- Cooling System

- Water Cooling

- Control System

- PLC with Touch Screen HMI

- Model No

- PRSL-SB-2200

- Voltage

- 380V (Customizable)

- Features

- High Automation, Stable Output, Energy Efficient, Low Maintenance

- Machine Type

- PVC Sheet Extrusion Line

- Frequency

- 50/60 Hz

- Accuracy

- 0.1 mm

- Power Rating

- 3 Phase, 380V / Customized

- Noise Level

- < 80 dB

- Lubricating System

- Centralized Automatic Lubrication

- Production Capacity

- 400-800 kg/h

- Frame Type

- Heavy Duty Steel

- Plastic Processed

- PVC (Polyvinyl Chloride)

- Product Type

- Production Line

- Technology

- Extrusion Technology

- Power Source

- Electricity

- Operating Type

- Automatic

- Power

- 120-180 kW (Depending on Configuration)

- Pressure

- Adjustable, typically up to 18 MPa

- Surface Treatment

- Smooth / Matte / Glossy / Custom Options

- Dimension (L*W*H)

- 22000 x 3200 x 3200 mm (Approx.)

- Weight (kg)

- 14000 kg

- Color

- Standard / Custom

- Usage & Applications

- Industrial

- Applicable Materials

- PVC Powder / Compounds

- Roller Type

- Chrome Plated Cooling Rollers

- Heating Method

- Ceramic Band Heaters

- Max Sheet Width

- 1220 mm / 1600 mm / 2050 mm (Customizable)

- Gearbox Type

- High Torque, Low Noise

- Safety Features

- Emergency Stop, Overload Protection, Safety Guard

- Feeding System

- Automatic Gravimetric Dosing

- Sheet Thickness Range

- 1-8 mm

- Optional Accessories

- Corona Treater, T-Die, Online Printing Unit

- Die Material

- Alloy Steel - Nitrided for Corrosion Resistance

PVC Rigid Sheet Line For Sandwich Board Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets, , Per Month

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About PVC Rigid Sheet Line For Sandwich Board

Introducing the featured PVC Rigid Sheet Line for Sandwich Boardan acclaimed, trending solution for industrial sheet production. This first-rate machine offers a glorious combination of precision engineering and modern design, delivering customizable sheet thickness (1-8 mm) and width (up to 2050 mm). Its lustrous chrome-plated rollers, automatic gravimetric dosing, and advanced extrusion technology guarantee smooth, superb-quality surfaces in matte, glossy, or custom finishes. Engineered for energy efficiency, noise reduction (<80 dB), and robust safety (emergency stop, overload protection), it is the ultimate choice for large-scale, reliable production.

Exceptional Features & Broad Applications

The PVC Rigid Sheet Line for Sandwich Board boasts an array of advanced featuresincluding chrome-plated cooling rollers, centralized automatic lubrication, and high-torque, low-noise performance. This automatic extrusion line is ideal for manufacturing industrial-grade sandwich boards with consistent precision and customizable finishes. Its versatile design accommodates varied sheet dimensions and is suitable for both general and specialized PVC processing tasks in construction, advertising, packaging, and beyond.

Supply Ability, Sampling, and Export Markets

Our acclaimed PVC sheet line is offered at the lowest price, with options for competitive list price quoting and secure, export-standard packaging. We provide sample availability for serious buyers and guarantee reliable supply capacity to meet substantial orders worldwide. Major export markets include Asia, Europe, the Middle East, and Africa, supported by our expertise as a leading distributor, exporter, manufacturer, and supplier from China.

Exceptional Features & Broad Applications

The PVC Rigid Sheet Line for Sandwich Board boasts an array of advanced featuresincluding chrome-plated cooling rollers, centralized automatic lubrication, and high-torque, low-noise performance. This automatic extrusion line is ideal for manufacturing industrial-grade sandwich boards with consistent precision and customizable finishes. Its versatile design accommodates varied sheet dimensions and is suitable for both general and specialized PVC processing tasks in construction, advertising, packaging, and beyond.

Supply Ability, Sampling, and Export Markets

Our acclaimed PVC sheet line is offered at the lowest price, with options for competitive list price quoting and secure, export-standard packaging. We provide sample availability for serious buyers and guarantee reliable supply capacity to meet substantial orders worldwide. Major export markets include Asia, Europe, the Middle East, and Africa, supported by our expertise as a leading distributor, exporter, manufacturer, and supplier from China.

FAQs of PVC Rigid Sheet Line For Sandwich Board:

Q: How does the automatic gravimetric dosing system enhance the production process?

A: The automatic gravimetric dosing system ensures precise material measurement and consistent mixing, contributing to uniform sheet quality while reducing material waste during PVC extrusion.Q: What is the sheet thickness and width flexibility of this PVC rigid sheet extrusion line?

A: The machine offers a customizable sheet thickness range from 1 to 8 mm and accommodates varied sheet widths1220 mm, 1600 mm, or 2050 mmto meet diverse production requirements.Q: When should I use optional accessories like the corona treater or printing unit?

A: Optional accessories such as the corona treater or online printing unit are beneficial when surface treatment or in-line printing is required to enhance adhesion and add branding or information directly on the sheets.Q: Where is the PVC Rigid Sheet Line primarily exported, and how is it packaged for shipment?

A: The machine is mainly exported to Asia, Europe, the Middle East, and Africa. It is securely packaged in export-standard wrapping or crating to ensure safe transit and delivery.Q: What are the key safety features integrated into this extrusion line?

A: Key safety features include an emergency stop button, overload protection system, and a comprehensive safety guard, ensuring operator safety throughout production.Q: What benefits does the centralized automatic lubrication system provide?

A: The centralized automatic lubrication system minimizes maintenance intervals and enhances machine longevity by ensuring optimal lubrication of all critical moving components.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sheet And Board Production Line Category

PVC Roffing Sheet Extrusion Line

Price Range 25000.00 - 150000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Color : Standard (Blue/White/Grey)

Production Capacity : 6001200 kg/h

Power Source : Electricity

Frame Type : Heavy Duty Steel Frame

PVC Decoration Sheet Line

Price Range 25000.00 - 150000.00 INR / Set

Minimum Order Quantity : 1 Set

Color : Custom

Production Capacity : 400600 kg/hr

Power Source : Electricity

Frame Type : Heavy Duty

PVC Advertising Foam Sheet Line

Price Range 25000.00 - 150000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Color : White/Grey/Custom

Production Capacity : 500700 kg/hr

Power Source : Electricity

Frame Type : Heavy Duty Steel Frame

PVC Foam Board Line

Price Range 25000.00 - 150000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Color : White / Custom

Production Capacity : 4001200 kg/hr

Power Source : Electricity

Frame Type : Heavy Duty Modular Frame

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry